Custom CNC Machining Services

From prototypes to on-demand production parts, get an instant quote for your metal or plastic projects with our online CNC machining services. Choose from 40+ materials, 10+ surface finishes.

Instant CNC quotes & detailed DFM

Tolerances down to 0.01mm (±0.0004″ )

Machined parts as fast as 1 day

What is CNC Machining?

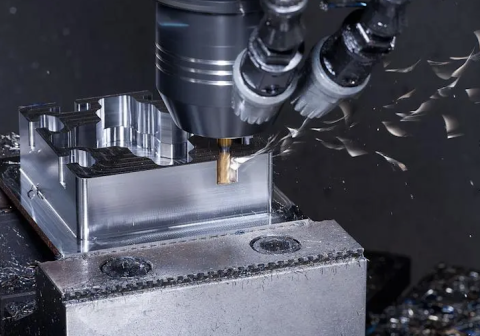

CNC or computer numerical control machining is a manufacturing process that uses automated, high-speed cutting tools to process materials.

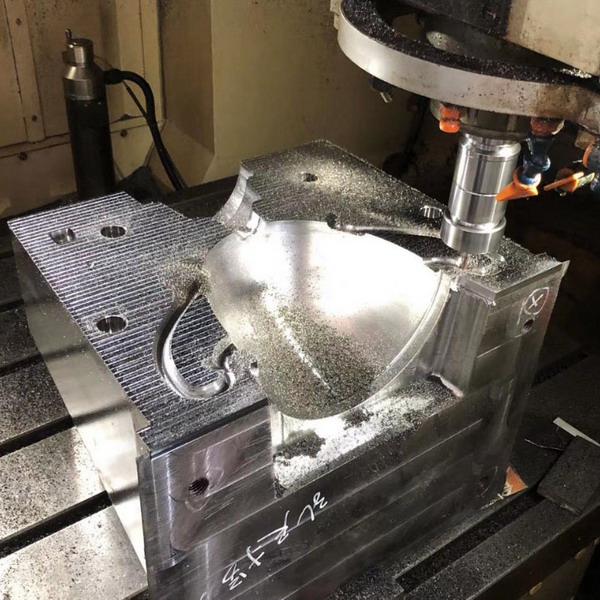

Programing Tool Paths

Based on the 3D file to optimize the tool paths to lower CNC machining cost as well as to achieve tight tolerance.

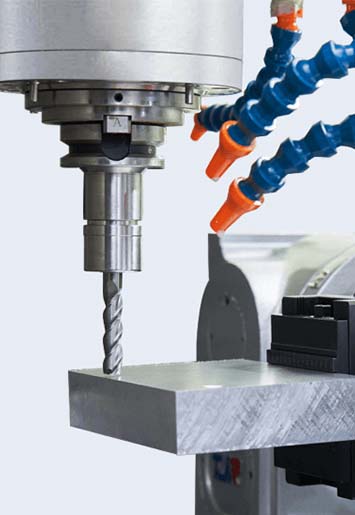

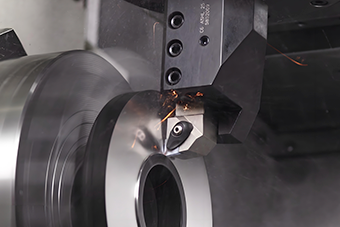

Cutting Tools on CNC

Tool material depends on the hardness of the processing material, processing requirements and economic considerations.

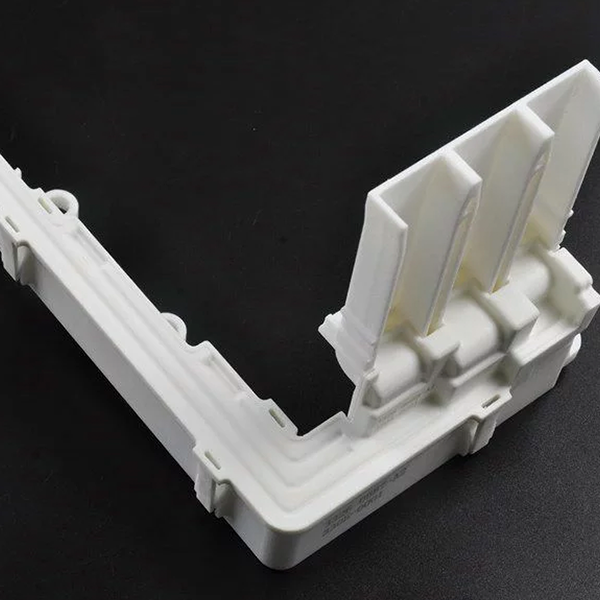

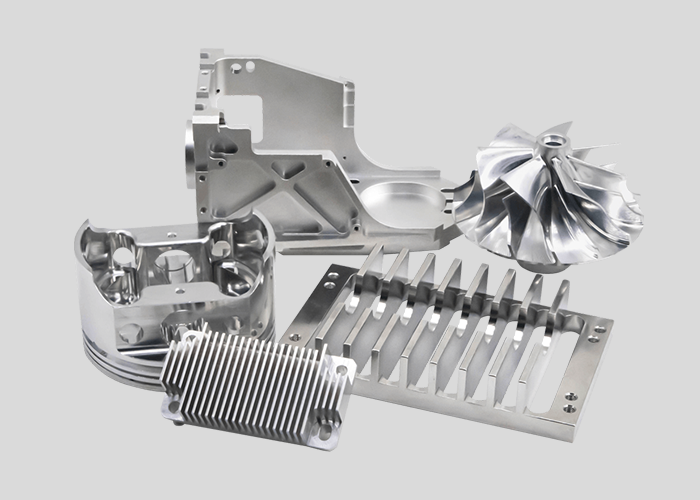

What products is CNC machining suitable for?

At XYX, our CNC machining services deliver parts made from a wide range of plastics and metals. We have reliable high-precision CNC mills, lathes, sink and wire EDMs and surface grinding machines excellent production capacity – enable us to deliver custom CNC machining for a wide variety of industries & clientele. Read more about our rapid prototyping solutions, or contact us today for free project review.

Milling (3, 4, 5 axis)

Whether they are horizontal boring machines or vertical milling centers (VMC’s), milling machines are the most popular thanks to their versatile 3+ axis machining capabilities.

Turning (2, 3, 4 axis)

Any round component such as a bolt/fastener, automotive wheel, or rocket nozzle is almost always produced on a CNC lathe, used for cylindrical components.

Wire EDM

Known for their extreme precision and repeatable accuracy, wire EDM machines use a combination of specialized water and electromagnetic current to remove very precise, human hair-sized cuts in a metal workpiece.

WHY CHOOSE US

Why Choose XYX Precision For CNC Machining Services

Precision, Quality and Affordability at any volume. Our team responds quickly to accommodate your needs.

• An Experienced Team with Expertise

• Advanced In-house Equipments

• Competitive Prices in the Industry

• One-To-One Collaboration & Proactive DFM

• High Complexity Machining Capability

• Industry-Leading Turnaround Times

Our CNC Machining Services

We provide a wide range of CNC machining services, including milling and turning various materials. Additionally, we offer drilling, tapping, EDM (Electrical Discharge Machining), and wire EDM. Our production process is ISO 9001 certified to ensure your parts are made accurately the first time, every time.

Custom CNC Milling Service

With 32 sets of 5-axis CNC milling machines in-house which allows us to mill tight tolerance plastic and metal parts with complex geometries easily. And we also offer low-cost machined parts by using our 3-, 4-axis milling machines.

Custom CNC Turning Service

EDM & Wire-Cut Service

CNC Grinding Service

Swiss Machining Service

CNC Routing Service

We Offer A Differentiated Custom Machining Service

XYX Precision with excellent CNC processing equipment and technology, to provide customers with differentiated customized processing services, successfully help 500+ customers to achieve product performance, from materials, processing to customized packaging, logistics and transportation “package” services also won the full recognition and praise of customers.

500+

Clients To Work With

95%+

Customer Satisfaction

60+

Exporting Country

Prototype Machining for Design Verification and Engineering Testing

Prototyping is a method where your design team creates plastic and metal parts using CNC (Computer Numerical Control) processing. This approach lets them closely mimic how the final product will look, function, and handle materials. It’s crucial for testing the components’ suitability and how easily they can be manufactured, which helps confirm and refine the design before full-scale production.

Custom Machining for Low-volume Production of End-use Parts

Get A CNC Machining Quote in 24 Hours

Fill in our quote form and we can provide pricing and feedback for your CNC Machined parts.

Case Applications Of CNC Machined Parts

CNC Machining Materials & Finishes

There are a wide variety of materials that can be machined using CNC technology, XYX provides CNC machining quotes for more than 30 engineering-grade plastic and metal materials. In terms of finishes, various types of surface finishes can be applied to CNC machined parts.

Plastic

ABS, PC, ABS+PC, PMMA(Acrylic), PA(Nylon), PA+GF30, POM(Acetal / Delrin), PP, PVC, HDPE, PPS, PEEK, PEI(Ultem), Teflon, Bakelite Resin, Epoxy Tooling Board.

Metal

Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper, Magnesium Alloy, Titanium Alloy, Zinc Alloy.

Finishes

We support one-stop CNC machining surface finishing to meet the visual and functional requirements of any design. Including sanding, sandblasting, mirror polishing, painting, printing, laser etching, anodizing, electroplating, nickel plating, chrome plating, powder coating, etc.

CNC Plastic Machining

CNC Metal Machining

Precision Machining Tolerance

XYX’s CNC machines operate with precision tolerances that meet industry standards, ensuring that every part is consistently accurate and fits perfectly with other components.

| General Tolerances | Metals : ISO 2768-m Plastics : ISO 2768-c |

| Precision Tolerances | XYX can manufacture and inspect parts with strict tolerances according to your drawing specifications and GD&T annotations, including tolerances tighter than +/- 0.001 inches. |

| Min Wall Thickness | 0.5mm |

| Min End Mill Size | 0.5mm |

| Min Drill Size | 1mm |

| Maximum Part Size | CNC Milling: 4000×1500×600 mm CNC Turning: 200×500 mm |

| Minimum Part Size | CNC Milling: 5×5 ×5 mm CNC Turning: 2×2 mm |

| Production Volume | Prototoyping: 1-100 pcs Low volume: 101-10,000 pcs High volume: Above 10,001 pcs |

| Lead Time | 5 bussiness days for most projects. Delivery of simple parts can be as fast as 1 day. |

Get a quote for what you need right away!

Your Easy Button

Get your custom metal parts pain free! Select a material type, enter your dimensions and quantity desired and add it to your quote cart. Then, submit your quote cart to The XYX and a representative will contact you.

Fast Turnaround

Fast Turnaround! To establish ourselves as a market leader, we have implemented a system which allows us to produce custom parts as fast as you need them.

Competitive Pricing

With the latest equipment and technology available in the precision machining industry, we are dedicated to producing orders for our clients in a quick and cost effective manner.

CNC Machining FAQs

In order to provide a meaningful quote, we require the following information:

We accept CAD data in any format, 2D and 3D, including STP, IGES, X_T, DWG, PDF, STL;

The expected quantities, machining processes, and raw materials required;

Any necessary secondary operations, including finishing specifications, heat treatment, anodizing or plating, etc.

Any applicable customer specifications, such as First Article Inspection, PPAP requirements, and required outside process certificates;

Any other useful information, such as target pricing or required lead times.

If you’re worried about Quality Assurance for international orders, an ISO-9001-certified factory won’t let you down. With dedicated inspection equipment and skilled QC/QA staff, we can provide 2D reports / CMM reports / 3D scan reports to ensure the quality of your parts is within the expected range.

100% of all dimensional tolerances, geometric tolerances, and print notes will be documented according to our MIL-STD-105E based statistical sampling plan with zero rejects. All dimensional inspection reports will be shipped with your parts.

More CNC Machining Resources

Mastering the Craft of Bronze Machining: A Comprehensive Guide

What are the Types of Turning Operations? A Detailed Guide

What is Plain Milling? Process, Types, and Comparison

Plain milling is a milling technique that uses cutter tools with teeth to remove material from a flat surface workpiece…

Quote Now to Start Your CNC Machining Project